Metal strips are versatile elements that can be used in various ways in interior design to add a touch of sophistication, modernity, or industrial flair to a space. Here are some common applications of metal strips in interior design:

TYPES OF METAL STRIPS USED IN INTERIOR DESIGN

- Tile Edging:

- Metal strips are often used as tile edging, providing a clean and finished look to tiled surfaces, particularly in bathrooms and kitchens.

- Transition Strips:

- Metal transition strips are employed between different types of flooring materials to create a smooth and aesthetically pleasing transition, such as between tile and wood or carpet.

- Furniture Detailing:

- Metal strips can be incorporated into furniture design as decorative accents or functional components, adding a contemporary touch to tables, chairs, or cabinets.

- Wall Accents:

- Vertical or horizontal metal strips on walls can serve as decorative accents, creating visually interesting patterns or acting as sleek design elements.

- Ceiling Design:

- Metal strips may be used to create decorative patterns on ceilings, especially in modern or industrial-style interiors. They can also be part of suspended ceiling systems.

- Detailing:

- Cabinet Metal strips can be applied to the edges of cabinets, providing both protection and a stylish design element.

- Stair Edging:

- Metal strips are used on stair edges for safety, creating a non-slip surface while contributing to the overall design of the staircase.

- Mirror Frames:

- Metal strips can be used to frame mirrors, offering a contemporary and clean design feature.

- Shelving Systems:

- Metal strips are often part of modular shelving systems, providing structural support and a modern appearance.

- Room Dividers:

- Metal strips may be incorporated into room dividers, adding an industrial or contemporary touch while defining separate areas within a space.

- Window Frames:

- Metal strips can be used as decorative framing around windows, contributing to the overall design of the window treatment.

- Art Installations:

- Creative applications of metal strips can include art installations or wall sculptures, adding a three-dimensional and dynamic element to the interior.

- Baseboard Detailing:

- Metal strips can be applied to baseboards, adding a unique design feature and protecting the edges of walls.

- Electrical Raceways:

- Metal strips may be used as part of a design-driven electrical raceway system, helping organize and conceal wiring in a visually appealing way.

- Curtain Rods and Rails:

- Metal strips can be used as curtain rods or rails, contributing to the overall window treatment design.

- Architectural Accents:

- Metal strips may be used as architectural accents, creating visual interest on walls, ceilings, or other surfaces.

The specific use of metal strips depends on the design goals, style preferences, and overall theme of the space. Designers often choose materials and finishes that complement the desired aesthetic and functionality of the interior.

Metal strips come in various types, each designed for specific purposes based on their composition, finish, and intended applications. Here are some common types of metal strips used in various industries, including construction and interior design:

- Aluminum Strips:

- Lightweight and corrosion-resistant, aluminum strips are commonly used in interior design for applications such as trim, edging, and decorative accents.

- Stainless Steel Strips:

- Known for its corrosion resistance and durability, stainless steel strips are used in a variety of applications, including appliances, kitchen backsplashes, and architectural detailing.

- Brass Strips:

- Brass strips offer an attractive golden appearance and are often used for decorative purposes, such as trim on furniture, cabinetry, and architectural accents.

- Copper Strips:

- Copper strips are appreciated for their distinctive reddish-brown color. They can be used decoratively in interiors, for example, as part of backsplashes or trim.

- Galvanized Steel Strips:

- Galvanized steel strips are coated with a layer of zinc for corrosion resistance. They are used in construction for applications like framing and structural components.

- Cold-Rolled Steel Strips:

- Cold-rolled steel strips are often used in manufacturing for their smooth finish. They can be utilized in various applications, including automotive components and construction.

- Hot-Rolled Steel Strips:

- Hot-rolled steel strips undergo a rolling process at high temperatures, resulting in a rougher surface. They are used in construction for structural components.

- Carbon Steel Strips:

- Carbon steel strips are versatile and widely used in various applications, including automotive manufacturing, construction, and general fabrication.

- Bronze Strips:

- Bronze strips, a mixture of copper and other metals, offer a warm and traditional appearance. They are used for decorative purposes and in the creation of sculptures.

- Zinc Strips:

- Zinc strips are often used as protective coatings for other metals or as a material for roofing applications due to their corrosion-resistant properties.

- Lead Strips:

- Lead strips are malleable and corrosion-resistant. They are used in specific applications, such as flashing in the construction industry.

- Nickel Strips:

- Nickel strips are known for their corrosion resistance and conductivity. They find applications in electronics and various manufacturing processes.

- Titanium Strips:

- Titanium strips are lightweight and corrosion-resistant. They are used in applications where a combination of strength and low weight is essential.

- Tin Strips:

- Tin strips are often used as a protective coating for other metals or in the manufacturing of tin cans.

- Perforated Metal Strips:

- These metal strips have holes punched through them, allowing for ventilation and decorative patterns. They are used in architectural and design applications.

The choice of metal strip depends on factors such as the intended application, environmental conditions, aesthetics, and budget. Each type of metal brings its own set of properties, and designers often select materials based on the specific requirements of a project.

Metal strips are versatile elements that can be used in various ways in interior design to add a touch of sophistication, modernity, or industrial flair to a space. Here are some common applications of metal strips in interior design:

- Tile Edging:

- Metal strips are often used as tile edging, providing a clean and finished look to tiled surfaces, particularly in bathrooms and kitchens.

- Transition Strips:

- Metal transition strips are employed between different types of flooring materials to create a smooth and aesthetically pleasing transition, such as between tile and wood or carpet.

- Furniture Detailing:

- Metal strips can be incorporated into furniture design as decorative accents or functional components, adding a contemporary touch to tables, chairs, or cabinets.

- Wall Accents:

- Vertical or horizontal metal strips on walls can serve as decorative accents, creating visually interesting patterns or acting as sleek design elements.

- Ceiling Design:

- Metal strips may be used to create decorative patterns on ceilings, especially in modern or industrial-style interiors. They can also be part of suspended ceiling systems.

- Cabinet Detailing:

- Metal strips can be applied to the edges of cabinets, providing both protection and a stylish design element.

- Stair Edging:

- Metal strips are used on stair edges for safety, creating a non-slip surface while contributing to the overall design of the staircase.

- Mirror Frames:

- Metal strips can be used to frame mirrors, offering a contemporary and clean design feature.

- Shelving Systems:

- Metal strips are often part of modular shelving systems, providing structural support and a modern appearance.

- Room Dividers:

- Metal strips may be incorporated into room dividers, adding an industrial or contemporary touch while defining separate areas within a space.

- Window Frames:

- Metal strips can be used as decorative framing around windows, contributing to the overall design of the window treatment.

- Art Installations:

- Creative applications of metal strips can include art installations or wall sculptures, adding a three-dimensional and dynamic element to the interior.

- Baseboard Detailing:

- Metal strips can be applied to baseboards, adding a unique design feature and protecting the edges of walls.

- Electrical Raceways:

- Metal strips may be used as part of a design-driven electrical raceway system, helping organize and conceal wiring in a visually appealing way.

- Curtain Rods and Rails:

- Metal strips can be used as curtain rods or rails, contributing to the overall window treatment design.

- Architectural Accents:

- Metal strips may be used as architectural accents, creating visual interest on walls, ceilings, or other surfaces.

Source – BUILD Magazine

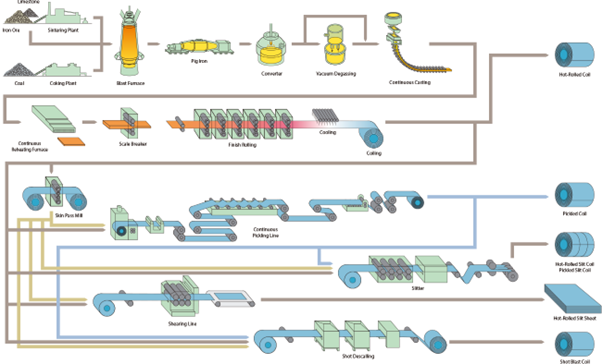

THE PROCESS OF MAKING METAL STRIPS

The process of making metal strips involves several steps, and the exact method can vary depending on the type of metal and the desired characteristics of the strips. Here’s a general overview of the process:

- Material Selection:

- The first step is selecting the type of metal for the strips. Common metals used include aluminum, stainless steel, brass, copper, and various alloys. The choice of metal depends on factors such as durability, corrosion resistance, and appearance.

- Metal Casting or Smelting:

- If the metal is not in the form of a raw ingot, it might be produced through casting or smelting. This involves melting the metal and pouring it into molds to create the desired shape.

- Hot Rolling:

- Hot rolling is a process where the metal is passed through a series of rollers while it is still at an elevated temperature. This helps shape the metal into thinner and longer pieces. The hot rolling process reduces the thickness and increases the length of the metal.

- Cold Rolling:

- Cold rolling is the next step where the hot-rolled metal undergoes further reduction in thickness at room temperature. This process helps achieve the desired thickness and surface finish.

- Annealing:

- Annealing is a heat treatment process that involves heating the metal strips to a specific temperature and then slowly cooling them. This process relieves stresses in the metal and improves its properties, such as hardness and ductility.

- Surface Treatment:

- Metal strips may undergo surface treatments depending on the desired finish. This could include processes like polishing, coating, or plating to enhance appearance, corrosion resistance, or other properties.

- Slitting:

- The metal strip is then slit into narrower widths according to the specifications. This process is known as slitting and is crucial for creating strips of the desired size.

- Coiling:

- After slitting, the metal strips are coiled into rolls for easier handling, transport, and storage.

- Quality Control:

- Throughout the manufacturing process, quality control measures are implemented to ensure that the metal strips meet the required standards. This may involve testing for thickness, hardness, surface finish, and other properties.

- Packaging and Distribution:

- The final step involves packaging the metal strips and preparing them for distribution. The strips are often shipped to manufacturers, construction sites, or other locations where they will be used.

It’s important to note that the specific steps and technologies used can vary based on the type of metal and the intended application of the strips. Additionally, advancements in technology and manufacturing processes can lead to variations in how metal strips are produced.

Get Free Design

About Author nikita

You May Also Like…

The Ultimate Guide to Small Modular Kitchen Designs in 2024

A brief overview of Small Modular Kitchen DesignThe space...

Top 10 TV Unit Designs to Enhance Your Home Interiors

Television unit designs have changed in response to changing...